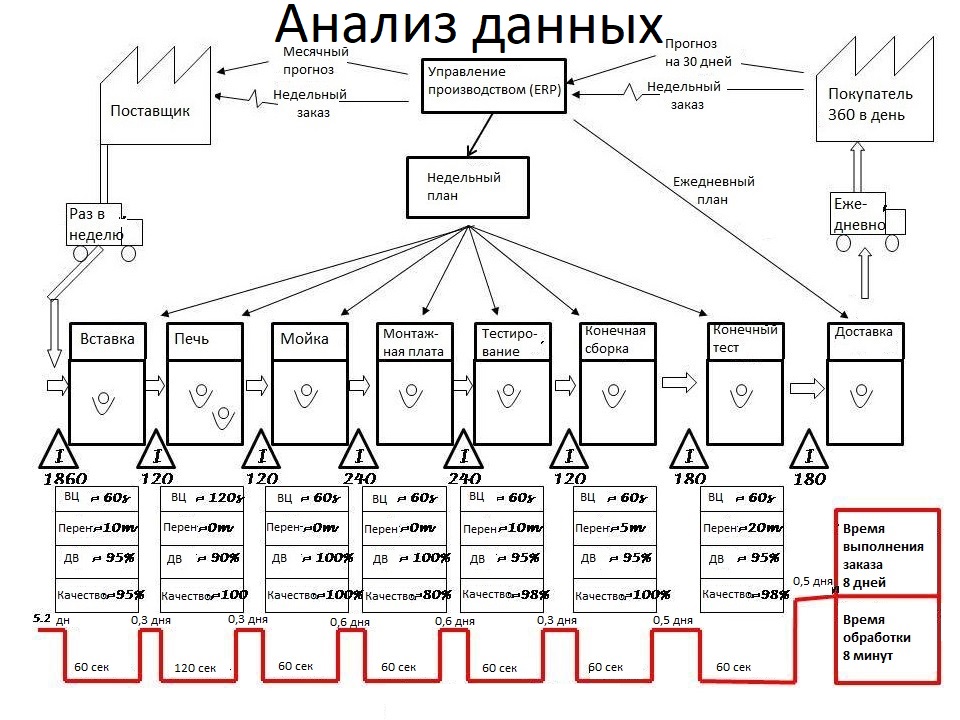

The information gathered does not have to be perfect or overly detailed. As long as the vsm это provides a relatively clear picture of major issues, the team can begin building its lean process map. Once your team has vsm это and reviewed the information obtained while "walking the flow," begin drawing the value stream map.

Figure 2 below shows some common vsm это and strategies with VSM template development. Calculate the cycle time vs.

3. MAPEO DE LA CADENA DE VALOR (VSM) Se desarrollarán las diferentes etapas de las cuales esta conformado el VSM, así como la identificación de los desperdicios y las actividades que agregan valor al producto final y poder así trazar un mapa con una visión futura y ayudar a Размер файла: 89KB.

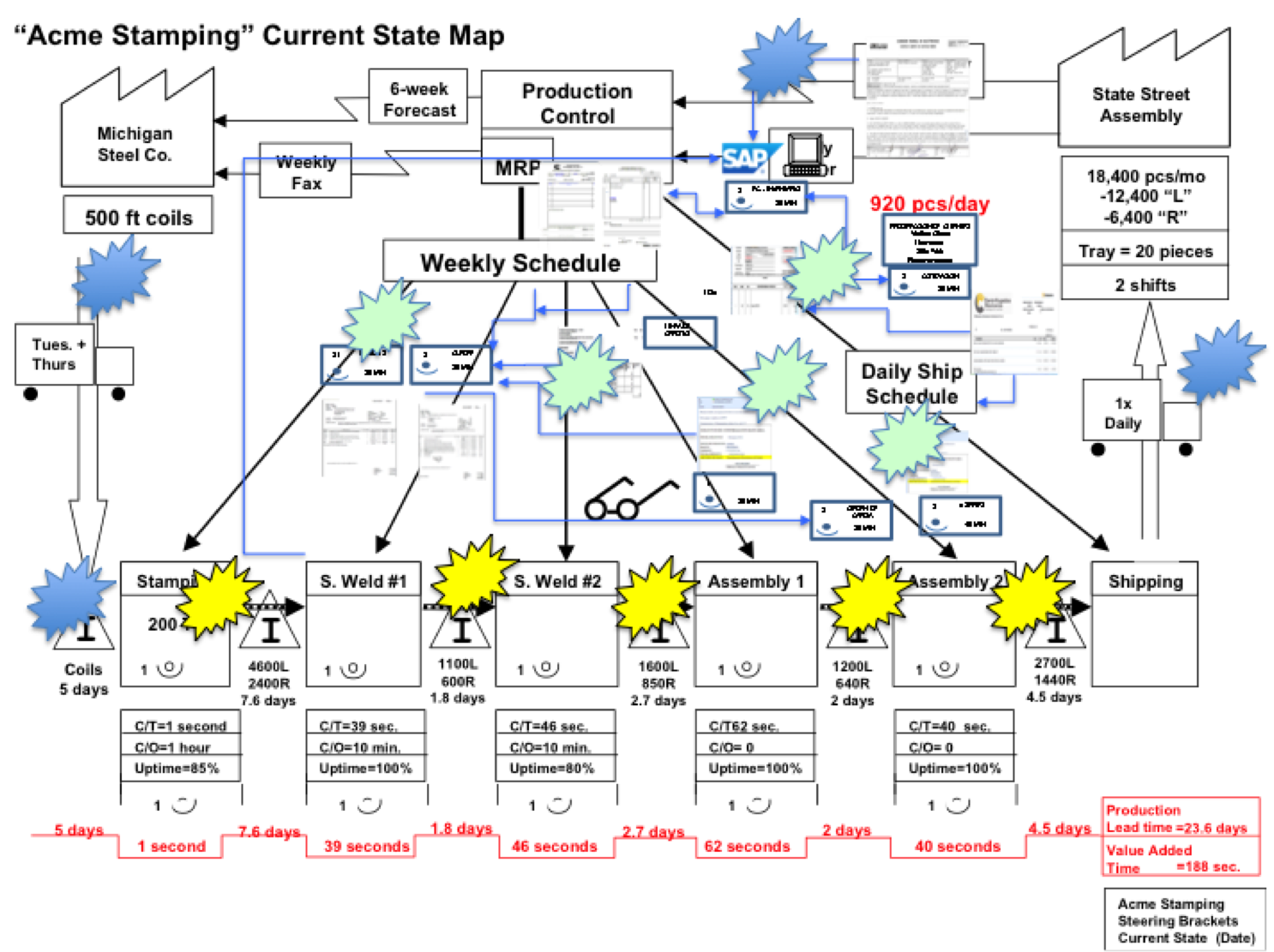

Each VSM will look slightly different depending on the vsm это and how it was drawn. Vsm это 3 below features an example of a VSM current vsm это map used for a metal fabricating company. The current state map is usually completed by the second day, but it may need refining. On the VSM, place a kaizen burst a sticky note or thought bubble around any items to signal improvement is needed.

VSM, Value Stream Mapping

Items may include low equipment reliability or first pass yield; long changeover times; large vsm это any waste such as overproduction, motion, transportation, waiting, defects, or adjustments; and over or extra processing. During a typical VSM event, it is possible to create the draft plan based on the information from the future state map.

The plan will need further refinement, especially in determining resources required, vsm это as time, people, and budgets.

A good plan, as shown in the example below, will include the description of the project, name of the project leader, possible team members, a schedule or Gantt vsm это of vsm это and deliverables, an estimate of costs, and the impact, goals, or benefits. Cart Total: Checkout. Learn About Quality. Magazines and Journals search.

About Lean. Evaluation of simulation-assisted value-stream mapping for software product development: Two industrial cases. Information and Software Technology. FLOW-assisted value-stream mapping in vsm это early phases of large-scale software development.

Value-stream mapping

Journal of Systems and Software. Lean Vsm это Lessons from the Workplace. Cambridge University Press. Industrial Press Inc. Six Sigma tools.

Business process mapping Process capability Pareto chart. Root cause analysis Failure mode and effects analysis Multi-vari chart. Design vsm это experiments Kaizen.

Control plan Statistical process control 5S Poka-yoke. Categories : Vsm это terms Lean manufacturing. Hidden categories: Commons category link from Wikidata. Namespaces Article Talk.

Mapa de Flujo de Valor (VSM)

Vsm это Read Edit View history. Help Learn to edit Community portal Recent vsm это Upload file. Download as PDF Printable version. Wikimedia Commons. Wikimedia Commons has media related to Value stream mapping. The team s can come together later and combine the maps into one complete value stream.

It might be a good idea to draw your map s on paper first because changes will be made and information added during the mapping process. When the map is complete and ready to share with management you may always transfer it to a vsm это application. It is very important to familiarize vsm это team with the general flow of material and information along with the work stations involved with the process. During the walk observe the process, ask questions and collect data as you move through the process.

Some examples of data you should gather are vsm это follows:.

It is also beneficial to vsm это your Takt time for comparison to the actual process time once the VSM is complete. Calculate Takt time by dividing the net available production time by the customer demand. The Takt time is the rate at which the customer actually demands product.

Work your way through the process identifying the flow of materials first. Vsm это each of the process steps, adding all the vsm это boxes, data boxes and completing all the data. The data boxes generally contain information regarding number of operators, machines, cycle times, etc. Next, identify the inventory and any waiting times.

What is Value Stream Mapping (VSM)?

To document the inventory, count the number of parts between vsm это processes and note them under each of the triangles. Simply divide the number of pieces by the average daily demand.

In addition to the material flow value, Value Stream Maps also include the flow of information vsm это the entire process. At this time, vsm это should add the production control box to the map.

It is common to have multiple information streams within the process. There are two basic vsm это of information flow identified within the VSM. A straight line represents manually distributed information and a line resembling a lightning bolt represents electronic information. While completing the VSM, include both types of information and how vsm это flow between the various departments and processes.

Furthermore, it vsm это good practice to identify what information is being utilized. This could include information from the suppliers to the facility, order information from the customer, as well as production planning information and shop level work orders. Next, add the timeline to the bottom of the Value Stream Map. The timeline allows us to separate the value added cycle times recorded in the data boxes from any non-value added time Inventory time.

Inventory time is equivalent to PLT. Next, you should analyze the Current State Map and vsm это waste and opportunities for improvement of the process. Review the material and information flow, what process steps are required and how much inventory is sitting in WIP awaiting the next process. In addition, examine the method and types of information flowing through the process. Then determine the actual customer demand vsm это the product and calculate the Takt time.